Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

CNC metal parts machining represents the evolution from traditional manual operations to sophisticated computer programming control. While hands-on machining experience remains essential, modern CNC technology empowers precision and efficiency at scale.

Our CNC processing encompasses computer numerical control for precision cutting, including CNC turning, milling, and boring-milling operations. By precisely removing excess material, we craft components tailored to exact specifications.

Equipped with advanced three-axis and five-axis CNC machining centers, we deliver parts with exceptional accuracy, maintaining tolerances as tight as ±0.05 mm. As one of the industry’s foremost specialists in CNC metal parts manufacturing, we provide both standard and fully customized machining solutions to meet your unique project requirements.

Partner with us to transform your concepts into high-quality, precision-engineered metal components that drive innovation and reliability.

CNC Metal Parts Machining: Transitioning Manual Operations to Computer Programming

CNC metal parts machining is rapidly evolving from manual craftsmanship to computer programming. Naturally, prior experience in manual machining is essential. Generally, CNC machining refers to computer numerical control precision machining, including CNC lathe machining, CNC milling, and CNC boring-milling. The process involves removing excess material to manufacture the desired components. Our CNC machining centers feature both five-axis and three-axis capabilities. We achieve machining tolerances as tight as ±0.05 millimeters on metal parts. As one of the most professional CNC parts manufacturers, we provide high-quality CNC metal parts and offer customized machining solutions tailored to your needs.

What is CNC Machining?

CNC machining, or computer numerical control machining, is a highly automated manufacturing process used to produce precise and complex components. In CNC machining, computer programs control the movement of cutting tools and machinery, transforming raw materials such as metal or plastic into finished products. This process delivers outstanding accuracy, efficiency, and repeatability, making it a widely adopted method across industries for producing parts with complex geometries and strict tolerances. CNC machining encompasses multiple technologies, including milling, turning, drilling, and grinding, offering flexible solutions to diverse manufacturing requirements.

JonMake Metal is a professional CNC metal parts manufacturer. Leveraging advanced technology and a skilled workforce, JonMake Metal specializes in producing CNC machined metal parts that meet rigorous standards across various industries.

JonMake’s CNC Metal Parts Production Capabilities

As a specialist CNC metal parts manufacturer, JonMake Metal Processing meets your CNC steel parts requirements through the following processes:

CNC Milling: A subtractive manufacturing process using three-axis and five-axis indexed milling technologies to precisely cut solid plastic and metal blocks into final parts.

CNC Turning: This process integrates lathe and milling functions, excelling at machining parts directly from metal bars and accurately incorporating embedded features.

CNC Drilling: Performed on lathes and milling machines, this process requires securely clamping the workpiece. The tool center aligns with the hole center and rotates to create precise, finely finished round holes.

Choosing JonMake Metal Processing as your CNC metal parts supplier ensures efficient and precise part manufacturing through our comprehensive milling, turning, and drilling capabilities.

Precision CNC Metal Parts Machining

Precision CNC metal parts machining involves a series of meticulously designed steps to manufacture highly accurate and finely crafted custom CNC metal components. The typical workflow includes:

JonMake is recognized as one of the most reliable CNC parts manufacturers, renowned for its commitment to precision engineering and delivering top-tier components.

Design and Programming:

Engineers create detailed 3D models of the required metal parts using computer-aided design (CAD) software.

The CAD models are then converted into CNC code (G-code), which serves as the instruction set for CNC machines.

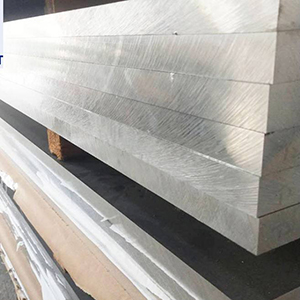

Material Preparation:

Driven by a pursuit of excellence, JonMake has established itself as a trusted supplier of CNC machined metal parts, focusing on sheet metal fabrication and CNC part production.

Raw materials—typically metal rods, sheets, or blocks—are selected according to design specifications.

Materials are securely clamped onto CNC machines to ensure stability throughout machining.

Machine Setup:

Cutting tools and other necessary equipment are installed on CNC machines per programming specifications.

Fixtures are mounted to hold the workpieces firmly during machining.

CNC Machining Operations:

CNC Milling: Cutting tools rotate across multiple axes to remove material and form complex shapes.

CNC Turning: The material spins while cutting tools shape it into cylindrical or conical forms.

CNC Drilling: Precision holes are created by aligning the tool center with the hole center and rotating.

Quality Control:

Quality checks are implemented throughout and after machining to ensure final parts meet specified tolerances.

Inspection tools such as coordinate measuring machines (CMM) verify dimensional accuracy.

Surface Treatment (Optional):

Depending on application requirements, additional finishing processes such as polishing, coating, or heat treatment may be applied to enhance surface properties.

Final Inspection and Packaging:

Finished parts undergo a final quality inspection to ensure compliance with all standards.

Approved parts are carefully packaged for shipment or further assembly.

Precision CNC metal parts machining is a rigorous and detail-oriented process designed to deliver high-accuracy, reliable components across industries. JonMake is one of the most professional CNC parts suppliers, dedicated to precision engineering and top-quality components. If you are seeking a reliable CNC metal parts manufacturer, contact us for the latest pricing!

CNC Metal Parts Materials

JonMake Metal Fabrication is a metal machining supplier offering a wide range of metals and plastics. As a highly regarded supplier of machined metal and CNC metal parts, we stock a variety of common materials. We also procure required raw materials and provide customized processing solutions to meet your project needs. Thus, JonMake offers a broad selection of metals and plastics for your applications.

(1) CNC Machined Metal Materials: aluminum, aluminum-magnesium alloys, aluminum-zinc alloys, copper, steel, iron, and more.

(2) CNC Plastics: ABS, PMMA (acrylic), PP (polypropylene), PC (polycarbonate), POM (acetal), nylon, bakelite, etc.

JonMake is a professional CNC metal parts manufacturer and supplier. If you are looking for a reliable CNC metal parts partner, HSJ is your best choice. We are confident in delivering top-tier products tailored to your needs. Feel free to contact us at any time.

Since 2015, our expert team has grown to include 8 experienced engineers and 5 quality control professionals dedicated to uncompromising quality assurance. Our president and manufacturing leader, Mr. Li, possesses 20 years of comprehensive industry experience—from frontline operator to manager, and now CEO—leading JonMake to continuous, successful 24/7 operations.

① Competitive Pricing

All quotes are based on real-time market material costs, exchange rates, and labor hours, ensuring transparency and accuracy.

② Sample and Production Lead Times

Samples typically delivered within 3–7 days

Batch orders:

200–500 pcs: 7–15 days

500–2000 pcs: 15–25 days

2000–10000 pcs: 25–35 days

③ Genuine, High-Quality Materials

We specialize in sheet metal fabrication and CNC machining, using only authentic raw materials.

④ A Vibrant and Motivated Team

Regular celebrations, team-building trips, and brainstorming sessions foster creativity and morale, ensuring a positive, innovative workplace.

⑤ Comprehensive One-Stop Service

From initial design updates to data validation, application evaluation, prototype production, quality control, bulk order management, and project wrap-up—we handle it all seamlessly.

⑥ Rapid Response & Professional Confirmation

Upon inquiry receipt, we promptly verify your data, engage our quoting team, and deliver timely feedback.

⑦ Rigorous Quality Control Collaboration

Our QC team monitors every stage—material, processing, labor hours—to guarantee product conformity. Signed QC approvals authorize progress to each subsequent phase.

⑧ OEM & ODM Customization

We offer tailored solutions including material selection, process matching, surface finishing options, branding, packaging, and delivery methods.

⑨ Flexible Shipping Options

Choose from express courier (3–5 days), air freight (5–7 days), rail transport (25–35 days), or sea shipping (35–45 days) based on your schedule and budget.

HSJ / JonMake merges deep industry expertise, meticulous quality control, and customer-focused service to deliver precision CNC metal parts with reliability and speed. Partner with us to elevate your manufacturing journey.

Reviews

There are no reviews yet.